Overview

- Structural Steel Drill Line

- High Speed Carbide Drilling

- Milling

- 4-Axis Carbide Scribing

- Three Drill Assemblies

- 5-Station Tool Changers (3)

- Siemens Spindle Motors

- Minimum Quantity Lubrication

- Superior Clamping System

- Peddinghaus Control

- MultMaster Measurement System

- AccuMeasure System

- Raptor Software

- Countersinking

- Tapping

Capacity

Process

The Ideal Drill Line for Small to Large Fabricators

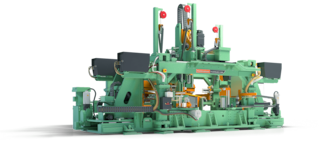

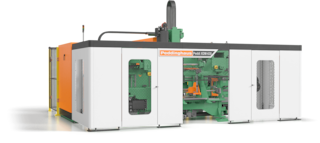

Peddinghaus has shaped today’s CNC beam drill line standard with time-tested technology. The Advantage-2 processes an average of 150 tons of steel per work week with the most efficient drilling, milling, scribing, tapping and countersinking operations.

What is Your Advantage?

The Advantage-2 carbide drill line utilizes automatic tool changing technology and completely electronic ball screw feed spindle motion. This combined with Peddinghaus' renowned build quality and mechanical design provide the ultimate combination of agility and strength.

High Speed Carbide Drilling

Powered by 25 HP (18.5 kW) Siemens spindle motors, the Advantage-2 is outfitted with 3 drill spindles, each equipped with 5-station tool changers. This powerful drilling technology allows for maximized operating time and drill hole quality.

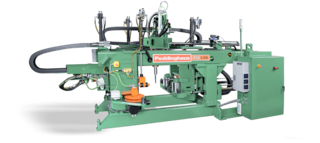

4-Axis Carbide Scribing

A 4-axis layout marking attachment eliminates human error in manual layout methods. Part information is retained even after painting, blasting and galvanizing.

Nonstop Throughput with Roller Feed Measurement

Peddinghaus’ Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.

Sturdy Drill Clamping to Eliminate Vibration

The Advantage-2 employs a series of support clamps in order to achieve optimum rigidity of the workpiece through the machine. Carbide tool life is best sustained with the least amount of vibration possible.

Band Saw Integration

The Advantage-2 CNC beam drill line with its powerful material handling support, meticulous measurement capabilities and high speed designs are ideal for tandem installations with any of Peddinghaus' automatic sawing systems.

AccuMeasure Allows Complete Handling Control

Saw measurement options are available via the Peddinghaus AccuMeasure Roller Feed measurement system. The AccuMeasure allows for complete handling versatility, while maintaining a streamlined CNC solution. Splitting apart a drill and a saw allows neither machine to wait for the other, maximizing production.

MultMaster Measurement System For Remnants

The MultMaster works as an extension of the Roller Feed measurement system in order to perform cuts which may otherwise require manual positioning for programs with many small pieces. This accessory allows fast and simple material processing on a Peddinghaus drill and saw tandem system by automating the processing of short remnant sections.

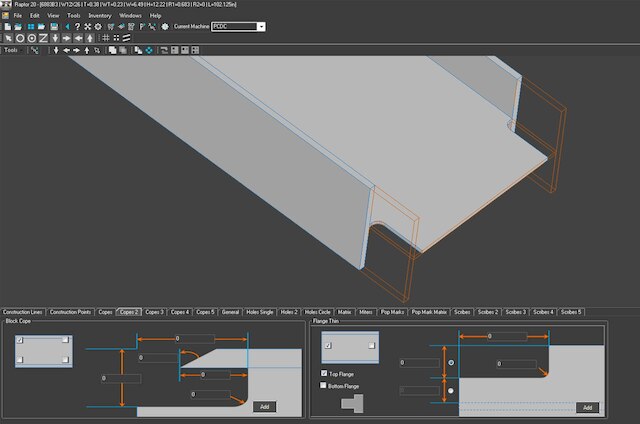

Raptor 3D CAD/CAM Software

Developed by Peddinghaus, Raptor 3D CAD/CAM Software takes CNC innovation further by enabling users to program faster and more accurately. Inspect, modify and export part information directly within the 3D platform. This coupled with Peddinghaus CNC technology means maximum capacity for fabricators.

The Ideal Drill Line for Small to Large Fabricators

Peddinghaus has shaped today’s CNC beam drill line standard with time-tested technology. The Advantage-2 processes an average of 150 tons of steel per work week with the most efficient drilling, milling, scribing, tapping and countersinking operations.

What is Your Advantage?

The Advantage-2 carbide drill line utilizes automatic tool changing technology and completely electronic ball screw feed spindle motion. This combined with Peddinghaus' renowned build quality and mechanical design provide the ultimate combination of agility and strength.

High Speed Carbide Drilling

Powered by 25 HP (18.5 kW) Siemens spindle motors, the Advantage-2 is outfitted with 3 drill spindles, each equipped with 5-station tool changers. This powerful drilling technology allows for maximized operating time and drill hole quality.

4-Axis Carbide Scribing

A 4-axis layout marking attachment eliminates human error in manual layout methods. Part information is retained even after painting, blasting and galvanizing.

Nonstop Throughput with Roller Feed Measurement

Peddinghaus’ Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.

Sturdy Drill Clamping to Eliminate Vibration

The Advantage-2 employs a series of support clamps in order to achieve optimum rigidity of the workpiece through the machine. Carbide tool life is best sustained with the least amount of vibration possible.

Band Saw Integration

The Advantage-2 CNC beam drill line with its powerful material handling support, meticulous measurement capabilities and high speed designs are ideal for tandem installations with any of Peddinghaus' automatic sawing systems.

AccuMeasure Allows Complete Handling Control

Saw measurement options are available via the Peddinghaus AccuMeasure Roller Feed measurement system. The AccuMeasure allows for complete handling versatility, while maintaining a streamlined CNC solution. Splitting apart a drill and a saw allows neither machine to wait for the other, maximizing production.

MultMaster Measurement System For Remnants

The MultMaster works as an extension of the Roller Feed measurement system in order to perform cuts which may otherwise require manual positioning for programs with many small pieces. This accessory allows fast and simple material processing on a Peddinghaus drill and saw tandem system by automating the processing of short remnant sections.