Overview

- Drill/Saw Combo

- High Speed Carbide Drilling

- Cope/Slot Milling

- 4-Axis Carbide Scribing

- Miter/Straight Cut Sawing

- Three Drill Assemblies

- 5-Station Tool Changers (3)

- Siemens Spindle Motors

- Minimum Quantity Lubrication

- Superior Clamping System

- Safety Guarding and Fencing

- Remnant Conveyor System

- Speed Sawing Technology

- PeddiCat Band Saw Blades

- Raptor Software

Capacity

Power

Multi-Spindle Drilling for Daily Part Processing

With the ability to be utilized as a primary fabrication system in a small to medium shop or to supplement a large shop, profiles up to 24" (630 mm) wide are processed with no stop in production.

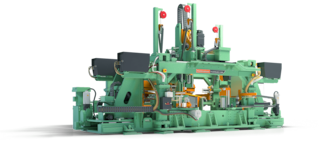

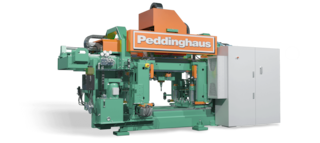

A True Processing Center

Peddinghaus has successfully fused drilling, sawing and coping operations into a single fabrication center. By combining a high-speed drill line with a double miter cut band saw, the Peddi XDM-630 CNC drill saw line executes drilling and sawing in harmony.

High Speed 4-Axis Carbide Drilling

Powered by 25 HP (18.5 kW) Siemens servo motors with a speed range of 0-3000 RPM, the Peddi XDM-630 is outfitted with 3 drill spindles, each equipped with 5-station tool changers. This powerful drilling technology allows for maximized operating time and drill hole quality.

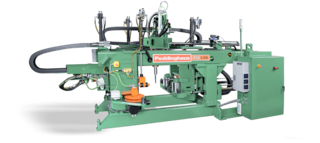

Slot and Cope Milling Functions

Slot and cope milling on the Peddi XDM-630 has been refined to produce a mirror-shine machined finish that completely eliminates grinding after drilling operations. Truly finished parts are ready for fit-up and require no further processing.

Nonstop Throughput with Roller Feed Measurement

Peddinghaus' Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.

Automatic Tool Changing Capabilities

Automatic tool changing comes standard on the Peddi XDM-630, eliminating the need to halt production for manual tool changes. All three spindles each support up to five tool changer stations.

Sturdy Drill and Saw Clamping to Eliminate Vibration

The Peddi XDM-630 CNC drill saw line employs a series of support clamps in order to achieve optimum rigidity of the workpiece through the machine. Carbide tool life is best sustained with the least amount of vibration possible.

Seamless Parts Handling Conveyor System

The Peddi XDM-630 offers convenient parts removal for minimal operator intervention. Short parts will be dumped into a scrap bin while longer parts will be conveyed through the exit of the system for further processing or unloading.

Band Saw Carriage System with Straight and Miter Cutting

An innovative traveling system transfers the saw to the profile for continual processing, eliminating manual positioning and manual measurement. The double miter design accommodates up to 60° cut angles both right and left, and allows for smooth processing of the entire profile with remnants as small as 13" (330 mm).

Speed Sawing Technology

Reduce cut times and increase productivity with these saw features: rapid advance blade approach, automatic material sensing, automatic cutting speed transition, feed compensation during the cut, end of cut sensing and automatic retract.

Protective Safety Guarding

To promote maximum shop floor safety, a modern machine guarding complete with two doors and fencing allows for easy maintenance access and clear visibility while the machine is in operation.

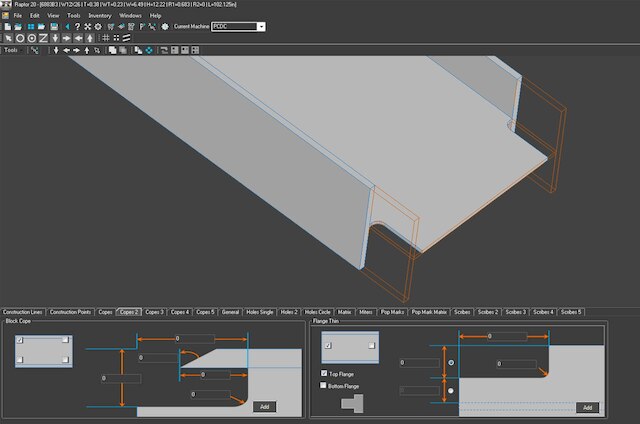

Raptor 3D CAD/CAM Software

Developed by Peddinghaus, Raptor 3D CAD/CAM Software takes CNC innovation further by enabling users to program faster and more accurately. Inspect, modify and export part information directly within the 3D platform. This coupled with Peddinghaus CNC technology means maximum capacity for fabricators.

Multi-Spindle Drilling for Daily Part Processing

With the ability to be utilized as a primary fabrication system in a small to medium shop or to supplement a large shop, profiles up to 24" (630 mm) wide are processed with no stop in production.

A True Processing Center

Peddinghaus has successfully fused drilling, sawing and coping operations into a single fabrication center. By combining a high-speed drill line with a double miter cut band saw, the Peddi XDM-630 CNC drill saw line executes drilling and sawing in harmony.

High Speed 4-Axis Carbide Drilling

Powered by 25 HP (18.5 kW) Siemens servo motors with a speed range of 0-3000 RPM, the Peddi XDM-630 is outfitted with 3 drill spindles, each equipped with 5-station tool changers. This powerful drilling technology allows for maximized operating time and drill hole quality.

Slot and Cope Milling Functions

Slot and cope milling on the Peddi XDM-630 has been refined to produce a mirror-shine machined finish that completely eliminates grinding after drilling operations. Truly finished parts are ready for fit-up and require no further processing.

Nonstop Throughput with Roller Feed Measurement

Peddinghaus' Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.

Automatic Tool Changing Capabilities

Automatic tool changing comes standard on the Peddi XDM-630, eliminating the need to halt production for manual tool changes. All three spindles each support up to five tool changer stations.

Sturdy Drill and Saw Clamping to Eliminate Vibration

The Peddi XDM-630 CNC drill saw line employs a series of support clamps in order to achieve optimum rigidity of the workpiece through the machine. Carbide tool life is best sustained with the least amount of vibration possible.

Seamless Parts Handling Conveyor System

The Peddi XDM-630 offers convenient parts removal for minimal operator intervention. Short parts will be dumped into a scrap bin while longer parts will be conveyed through the exit of the system for further processing or unloading.

Band Saw Carriage System with Straight and Miter Cutting

An innovative traveling system transfers the saw to the profile for continual processing, eliminating manual positioning and manual measurement. The double miter design accommodates up to 60° cut angles both right and left, and allows for smooth processing of the entire profile with remnants as small as 13" (330 mm).

Speed Sawing Technology

Reduce cut times and increase productivity with these saw features: rapid advance blade approach, automatic material sensing, automatic cutting speed transition, feed compensation during the cut, end of cut sensing and automatic retract.

Protective Safety Guarding

To promote maximum shop floor safety, a modern machine guarding complete with two doors and fencing allows for easy maintenance access and clear visibility while the machine is in operation.