55 Ton Ironworker

Peddinghaus has shaped today’s ironworker standard with a minimal footprint, versatile function, universal design and powerful punching technology. The PeddiCat hydraulic ironworker meets the needs of fabrication shop detail work, both large and small.

Our Most Economical Ironworker

With the 55 ton hydraulic press, the PeddiCat is able to punch and shear multiple shapes and sizes. Perfect for miscellaneous projects, shear up to 1/2" (12 mm) flat bar.

Robust Build for Longevity

As for all Peddinghaus machines, this ironworker follows suit by withstanding the test of time. Where it all started, is not an uncommon sight to see a Peddinghaus steelworker from the early 1900s still in operation within a fabrication shop. No ironworker boasts the track record of durability as Peddinghaus does.

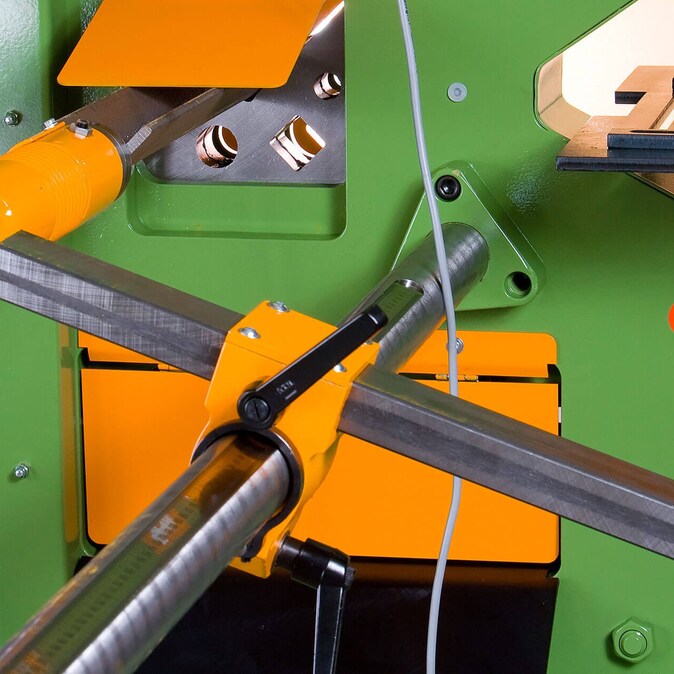

Length Stop

Perfect for mass production, the length stop feature on the PeddiCat diminishes guesswork for a constant operator feed.

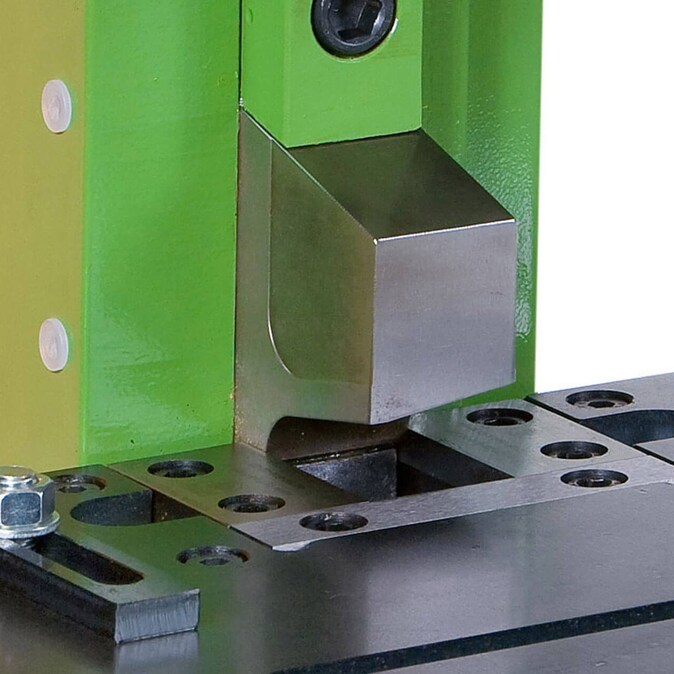

Notching and Bending

Additional bending tools add even more versatility to this hydraulic ironworker. Customize small parts even further with bending capabilities up to 4" (100 mm) angle.

55 Ton Ironworker

Peddinghaus has shaped today’s ironworker standard with a minimal footprint, versatile function, universal design and powerful punching technology. The PeddiCat hydraulic ironworker meets the needs of fabrication shop detail work, both large and small.

Our Most Economical Ironworker

With the 55 ton hydraulic press, the PeddiCat is able to punch and shear multiple shapes and sizes. Perfect for miscellaneous projects, shear up to 1/2" (12 mm) flat bar.

Robust Build for Longevity

As for all Peddinghaus machines, this ironworker follows suit by withstanding the test of time. Where it all started, is not an uncommon sight to see a Peddinghaus steelworker from the early 1900s still in operation within a fabrication shop. No ironworker boasts the track record of durability as Peddinghaus does.

Length Stop

Perfect for mass production, the length stop feature on the PeddiCat diminishes guesswork for a constant operator feed.

Notching and Bending

Additional bending tools add even more versatility to this hydraulic ironworker. Customize small parts even further with bending capabilities up to 4" (100 mm) angle.