Stay Ahead of the CNC Programming Curve

Raptor 3D CAD/CAM Software from Peddinghaus takes CNC innovation further by enabling users to program faster and more accurately from design BIM platforms. This coupled with Peddinghaus CNC technology means maximum capacity for fabricators and detailers alike.

Raptor Packages for Your Processing Needs

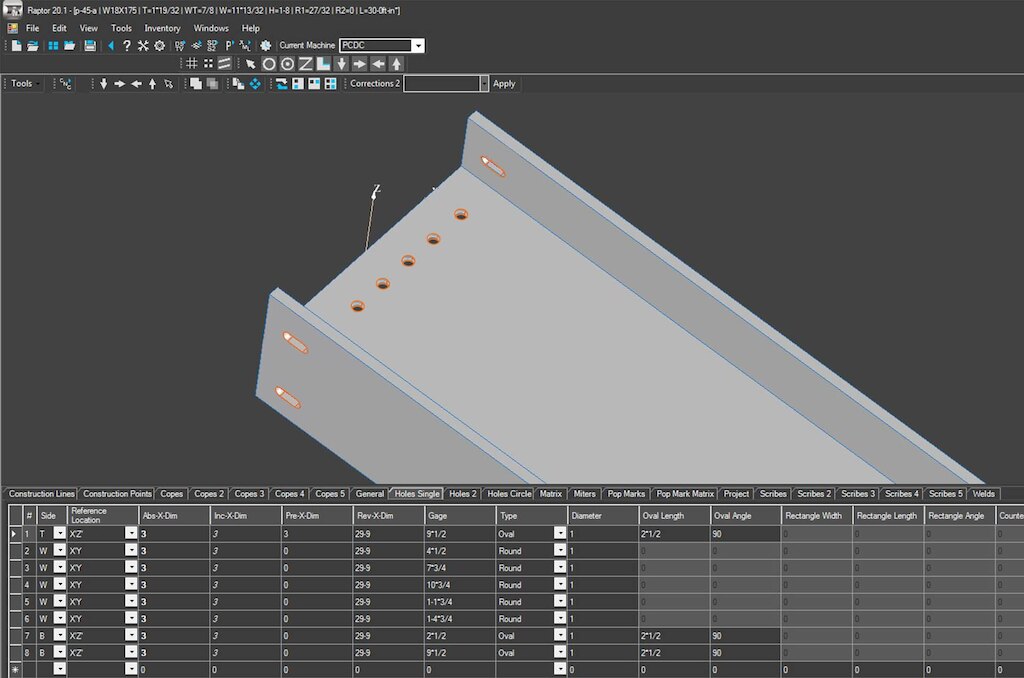

3D interface for examining & creating part data

Import DSTV files from building design (BIM) software

Export CNC part files for operation of machinery using CNC Post Processors

Enhanced & corrected DSTV export

Direct import of part data from Tekla

Inherits Raptor Light features

Compatible with PeddiMat

Parts Tracking

DXF Import

Inherits Raptor Light & Standard features

iDSTV+ & DSTV+ Import/Export for batch nested files

Inherits Raptor Light, Standard, & Pro features

We Are Stronger Than Steel

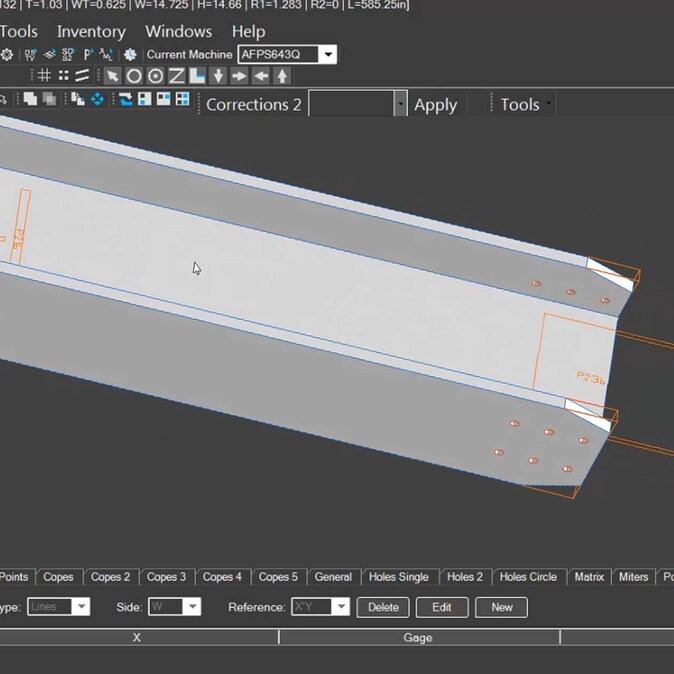

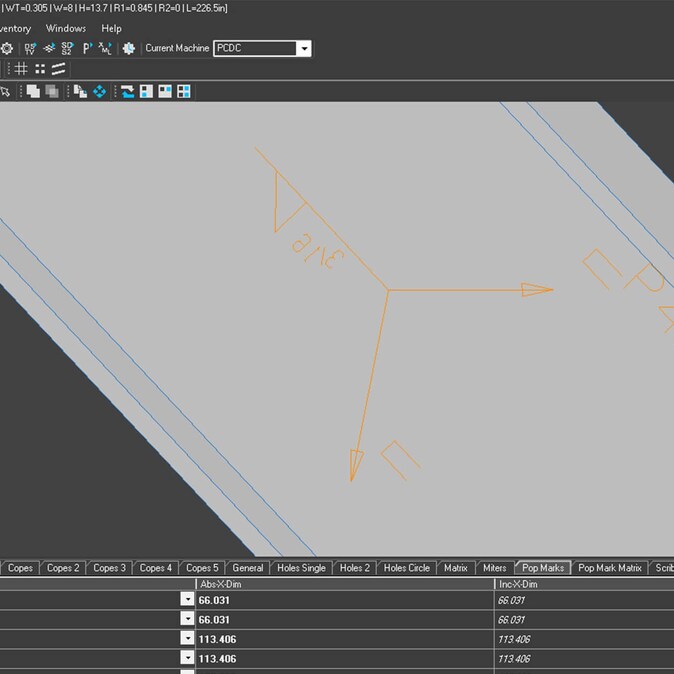

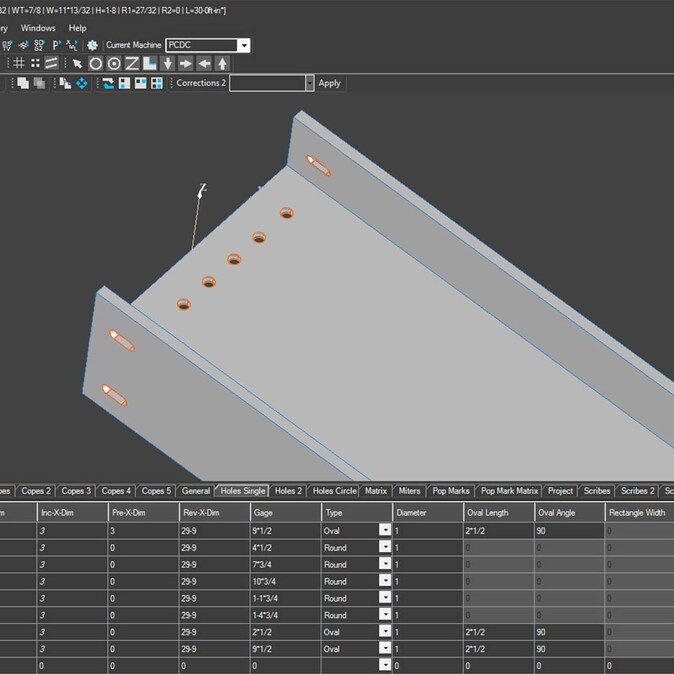

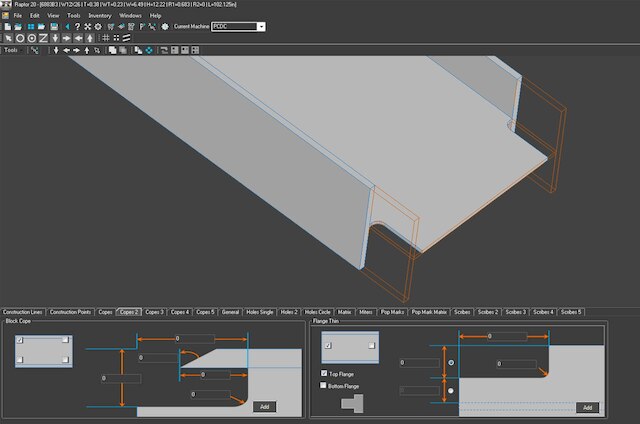

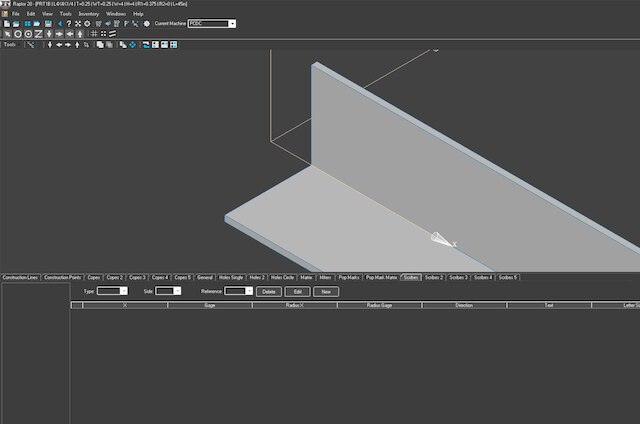

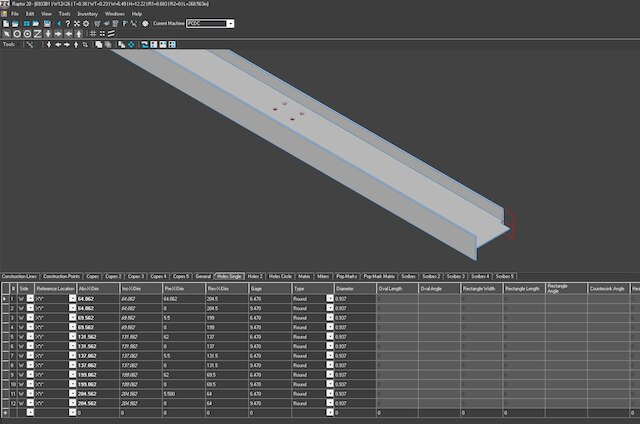

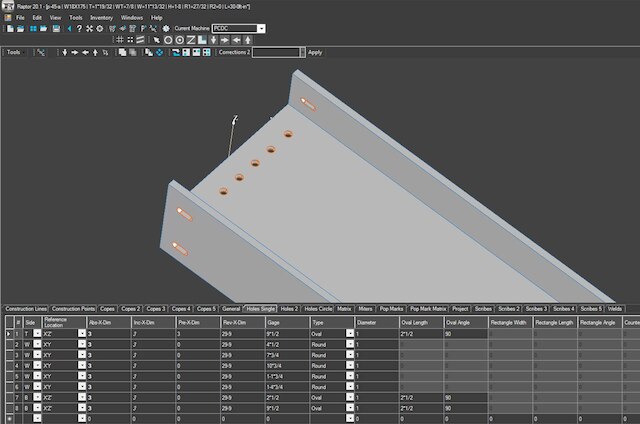

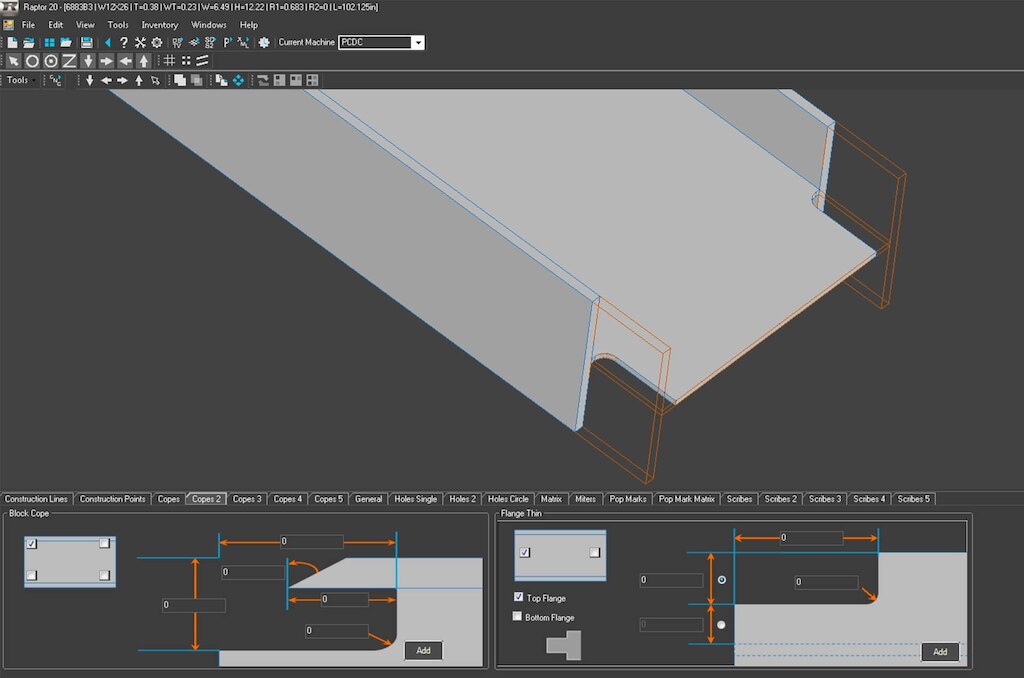

3D Module - The Core of Raptor

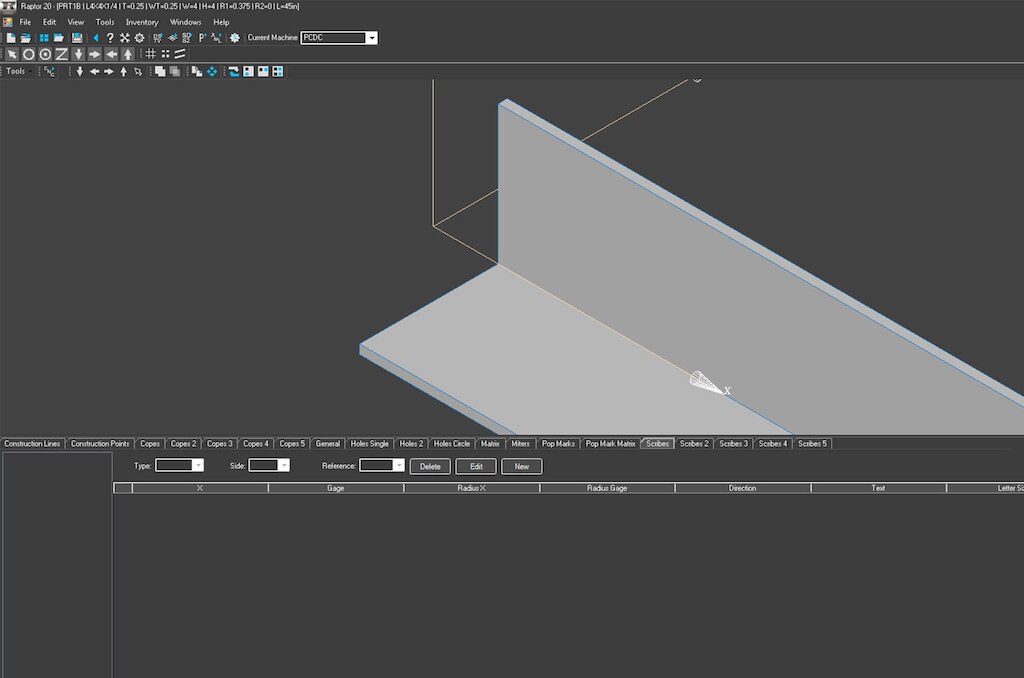

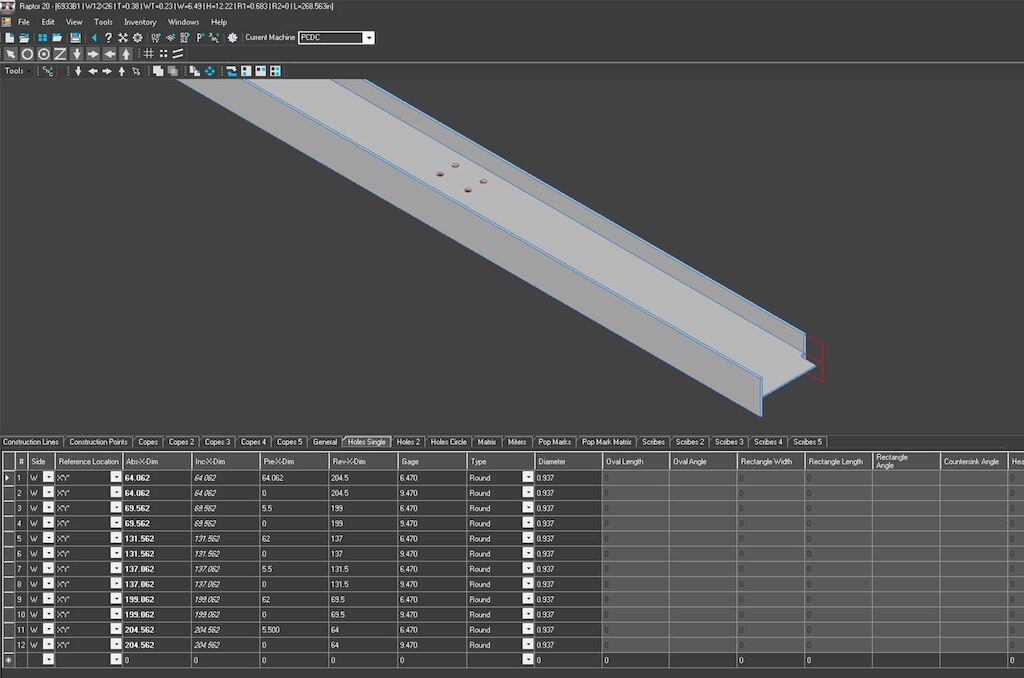

The heart of Raptor lies within the 3D module. Here is where the complete management and editing of part data occurs. When part data is imported into Raptor, inspect, modify and export part information directly within the 3D platform. If you desire to create part files, Raptor allows this via its intuitive design.

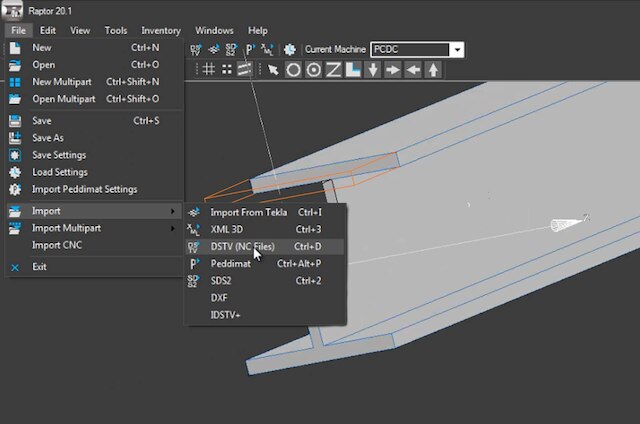

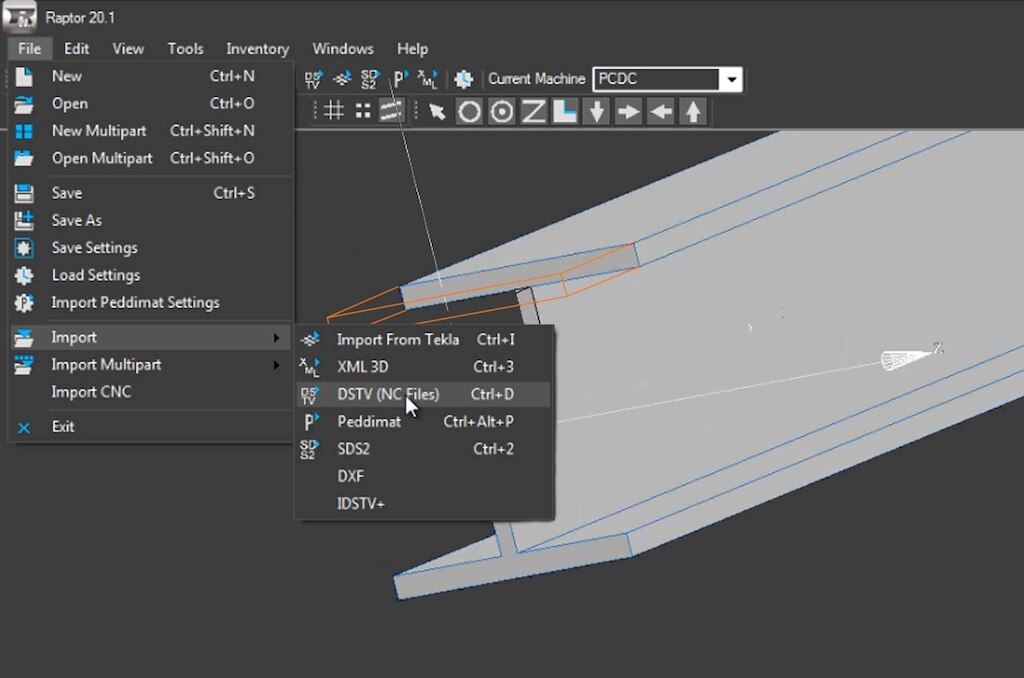

DSTV Import - Transfer BIM Files to the Common Standard

This module is available for fabricators who are already utilizing building design, or BIM, software. DSTV Import allows users the flexibility to transfer original designs from the model into the common DSTV file standard. The DSTV file is then imported into Raptor via the DSTV Import module for editing and modifying, or CNC file creation, for execution on a machine.

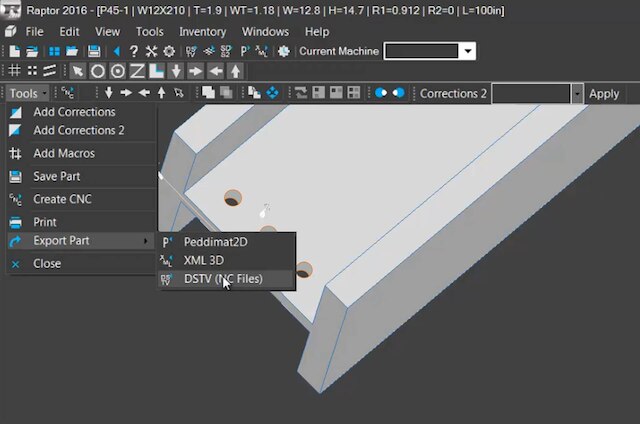

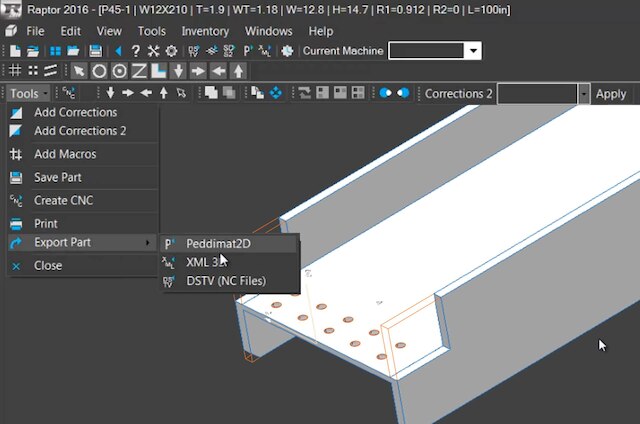

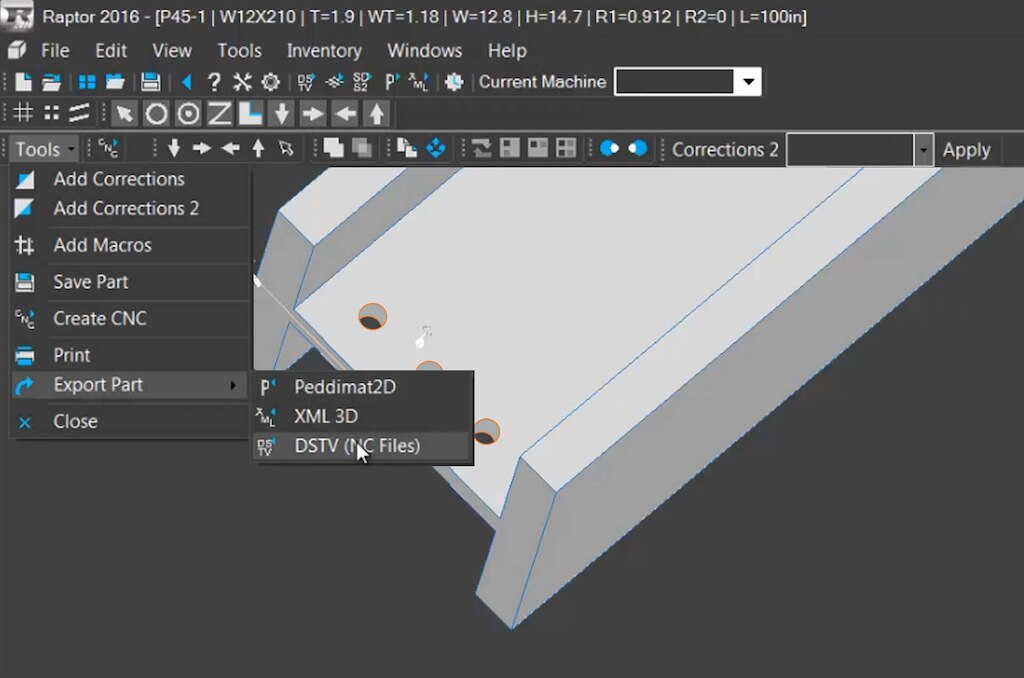

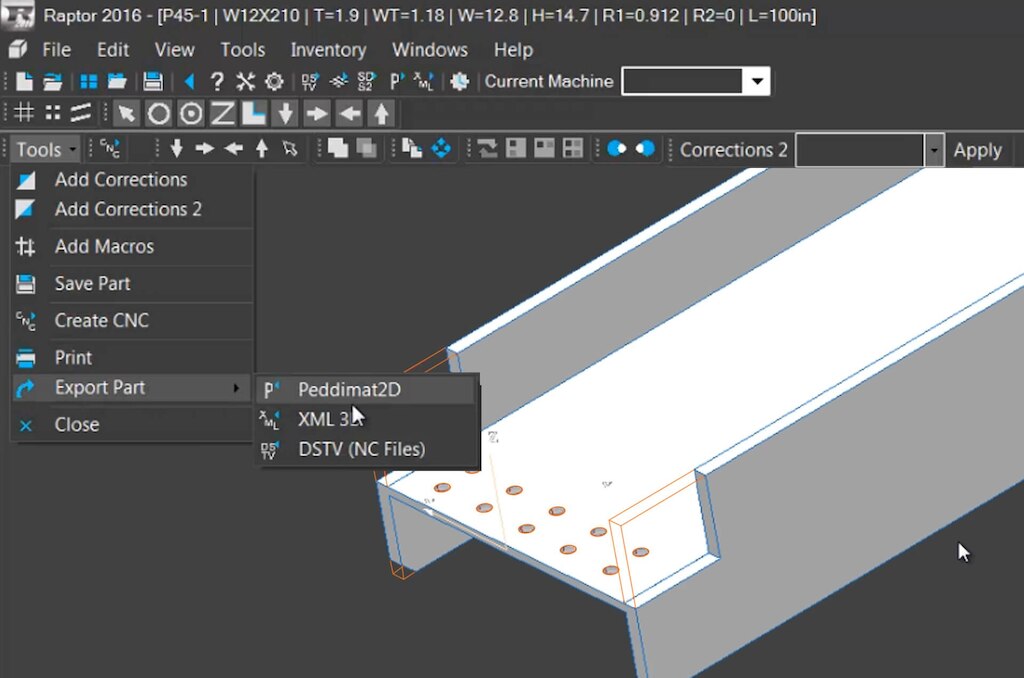

DSTV Export - Bring Raptor to Third Party CNC

Do you have CNC technology outside of Peddinghaus? The DSTV Export module is capable of exporting part information into a DSTV file format (scribes, copes and holes). All enhancements or corrections applied within Raptor are included within the DSTV file using this module. The DSTV Export module brings the power of Raptor to third party CNC machinery that can import files of this type.

Tekla API Import - Optimize BIM File Conversion

Users of this BIM software benefit with a direct connection to Raptor Software for optimized file conversions. This direct transfer sources the original design of the structure and allows for more accurate conversions. With no intermediary file conversions, end-users receive a more precise, data-rich import using this module.

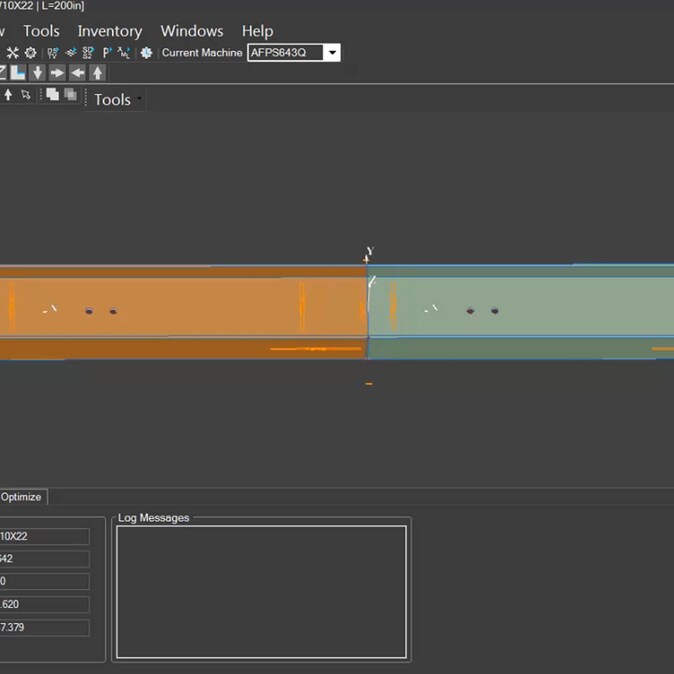

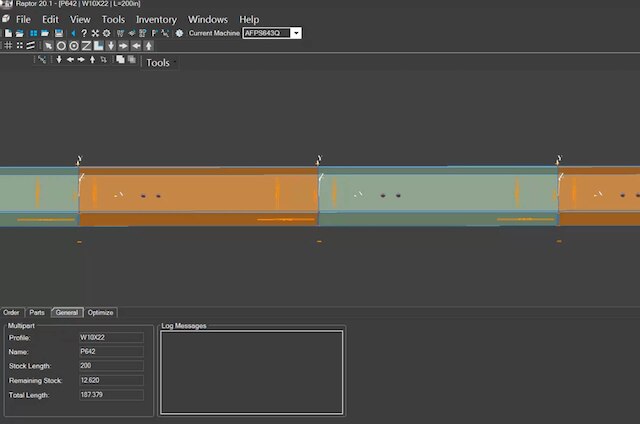

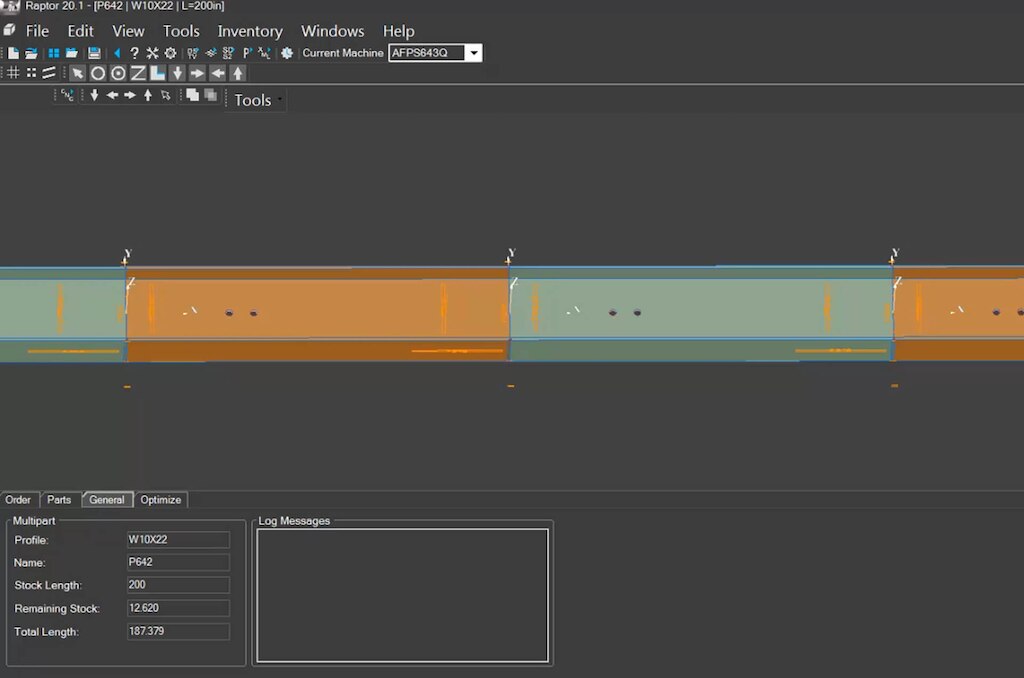

iDSTV+ and DSTV+ Import/Export - Eliminate Manual Batch Nesting

Select MRP (Material Requirements Planning) systems are capable of exporting batch nested files in a format known as iDSTV+ and DSTV+. These file types play an important role in the automated development of cut sheets for production which Raptor is capable of importing and exporting. Eliminate the need to manually batch nest files, which have already been batch nested within a third party MRP software.

Peddimat Import/Export - Translate Legacy Software

What if you are currently using Peddimat Software from Peddinghaus? The Peddimat Import/Export module provides users the ability to create new Peddimat files or utilize existing Peddimat files within Raptor. This module allows users complete flexibility in regards to legacy steel fabrication software compatibility.

Post Processor - Output Files to Machinery

A Post Processor is an interface between CAD/CAM packages such as Raptor and a particular piece of equipment. It works as a translator, reading the manufacturing instructions issued from a CAM system and writing an appropriate rendition for that specific machine. This means that each machine requires a different Post Processor. Raptor can output files for machines with developed Post Processors using no intermediary modules.

DXF Import - Utilize 2D CAD Software

Import DXF files from 2D CAD software with ease using this Raptor module. The DXF Import module is an opt-in module currently in beta testing.

Parts Tracking - Monitor Production

Searching for a better way to review and track production? The Parts Tracking module is for monitoring the production of parts on Peddinghaus machines using Siemens controls. Now available as an option with Raptor Software, the Parts Tracking module works in the background of the CNC control, creating output files that display vital information about parts production.

World-Class Training at PeddiUniversity

Production is only as good as your weakest or unskilled operator. Professional training is vital to the success of your CNC investment. At Peddinghaus, we understand that a well-trained employee helps increase productivity and profitability while promoting workplace safety. Take a proactive approach to training and resolve issues before they become one at PeddiUniversity.

Raptor Software Empowers Some of the World’s Most Successful Fabricators

Enter Today for a Chance to Win FREE Machinery

Gift cards and other Peddinghaus merchandise included

46331 mobile

TO

46331

WINNER

Normal text message rates apply. Text “STOP” to opt out. Text “HELP” for help. Up to 3 msgs / month. Terms https://www.peddinghaus.com/terms/1

Steel Fabrication Software

3D interface for examining & creating part data

Import DSTV files from building design (BIM) software

Export CNC part files for operation of machinery using CNC Post Processors

Enhanced & corrected DSTV export

Direct import of part data from Tekla

Inherits Raptor Light features

Compatible with PeddiMat

Parts Tracking

DXF Import

Inherits Raptor Light & Standard features

iDSTV+ & DSTV+ Import/Export for batch nested files

Inherits Raptor Light, Standard, & Pro features

Stay Ahead of the CNC Programming Curve

Raptor 3D CAD/CAM Software from Peddinghaus takes CNC innovation further by enabling users to program faster and more accurately from design BIM platforms. This coupled with Peddinghaus CNC technology means maximum capacity for fabricators and detailers alike.

Raptor Packages for Your Processing Needs

3D Module - The Core of Raptor

The heart of Raptor lies within the 3D module. Here is where the complete management and editing of part data occurs. When part data is imported into Raptor, inspect, modify and export part information directly within the 3D platform. If you desire to create part files, Raptor allows this via its intuitive design.

DSTV Import - Transfer BIM Files to the Common Standard

This module is available for fabricators who are already utilizing building design, or BIM, software. DSTV Import allows users the flexibility to transfer original designs from the model into the common DSTV file standard. The DSTV file is then imported into Raptor via the DSTV Import module for editing and modifying, or CNC file creation, for execution on a machine.

DSTV Export - Bring Raptor to Third Party CNC

Do you have CNC technology outside of Peddinghaus? The DSTV Export module is capable of exporting part information into a DSTV file format (scribes, copes and holes). All enhancements or corrections applied within Raptor are included within the DSTV file using this module. The DSTV Export module brings the power of Raptor to third party CNC machinery that can import files of this type.

Tekla API Import - Optimize BIM File Conversion

Users of this BIM software benefit with a direct connection to Raptor Software for optimized file conversions. This direct transfer sources the original design of the structure and allows for more accurate conversions. With no intermediary file conversions, end-users receive a more precise, data-rich import using this module.

iDSTV+ and DSTV+ Import/Export - Eliminate Manual Batch Nesting

Select MRP (Material Requirements Planning) systems are capable of exporting batch nested files in a format known as iDSTV+ and DSTV+. These file types play an important role in the automated development of cut sheets for production which Raptor is capable of importing and exporting. Eliminate the need to manually batch nest files, which have already been batch nested within a third party MRP software.

Peddimat Import/Export - Translate Legacy Software

What if you are currently using Peddimat Software from Peddinghaus? The Peddimat Import/Export module provides users the ability to create new Peddimat files or utilize existing Peddimat files within Raptor. This module allows users complete flexibility in regards to legacy steel fabrication software compatibility.

Post Processor - Output Files to Machinery

A Post Processor is an interface between CAD/CAM packages such as Raptor and a particular piece of equipment. It works as a translator, reading the manufacturing instructions issued from a CAM system and writing an appropriate rendition for that specific machine. This means that each machine requires a different Post Processor. Raptor can output files for machines with developed Post Processors using no intermediary modules.

DXF Import - Utilize 2D CAD Software

Import DXF files from 2D CAD software with ease using this Raptor module. The DXF Import module is an opt-in module currently in beta testing.

Parts Tracking - Monitor Production

Searching for a better way to review and track production? The Parts Tracking module is for monitoring the production of parts on Peddinghaus machines using Siemens controls. Now available as an option with Raptor Software, the Parts Tracking module works in the background of the CNC control, creating output files that display vital information about parts production.

World-Class Training at PeddiUniversity

Production is only as good as your weakest or unskilled operator. Professional training is vital to the success of your CNC investment. At Peddinghaus, we understand that a well-trained employee helps increase productivity and profitability while promoting workplace safety. Take a proactive approach to training and resolve issues before they become one at PeddiUniversity.