Overview

- Thermal Cutting/Coping Line

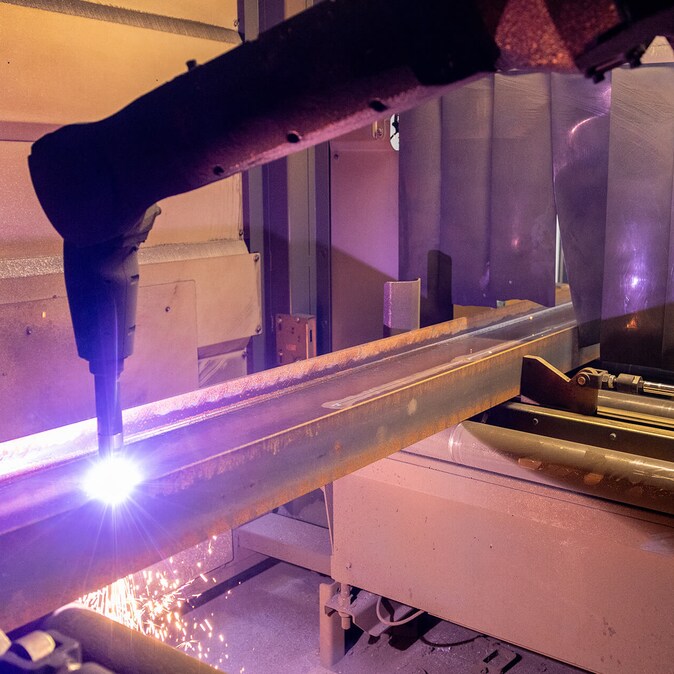

- Robotic Plasma Cutting

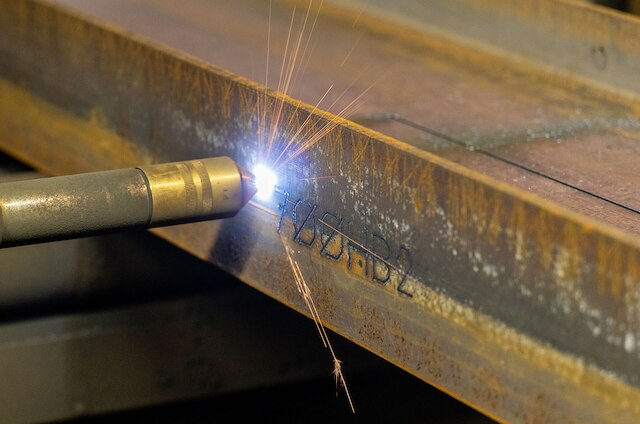

- Integrated Layout Marking

- Near Flange Cutting

- Bevel Cutting

- Fanuc Robot Arm

- FineLine Plasma Torch

- Rigid Cutting Cell

- Modular Control

Plasma

Bevel

The Most Powerful Solution on the Market

Introducing the newest member to the Peddinghaus robotic family: the PeddiBot-1100 robotic thermal processor. Designed to revolutionize your beam cutting production, this advanced technology comes with the latest-generation Fanuc high-performance industrial robot. Specialized torch movements throughout plasma cutting and layout marking eliminate the need for grinding, resulting in more savings and profit in your pocket.

FineLine Plasma Torch

The PeddiBot-1100 comes equipped with a FineLine 300HD (300 amp) plasma cutting system. The FineLine 300HD is designed to deliver fast cutting speeds, exceptional cut quality, precise repeatability and high reliability to maximize productivity. The quick-disconnect torch enables fast and simple changeover, minimizing machine downtime.

Fanuc Robot for Reliability

The PeddiBot-1100 comes with the latest-generation, six-axis, high-performance industrial robot. A built-in robot collision guard is designed to eliminate damage to the torch due to accidental collisions. Fanuc robots are engineered for extremely high speed applications, and are known for their reliability to deliver repeatable precision with unparalleled performance.

Near Flange Cutting

One of the biggest challenges during beam cutting is the transition area from web to flange. The PeddiBot-1100 executes fast cutting sequences based on plasma techniques to cut away scrap material. This produces clean and sharp edge finishes, which helps to reduce the need for secondary processing such as grinding for weld preparation.

Measuring Cart System

A high speed measuring cart located above the infeed conveyor is designed to maintain accurate positioning of the material. A Fanuc servo motor with a precision encoder drives the measuring cart on a rail with wheels. This measuring system follows the material by exerting pressure to contact the workpiece. The measuring cart uses force feedback to detect the end of beams and comes standard with a lift system for fast reloading.

Integrated Layout Marking

Multi-axis plasma layout marking is a long-lasting and economical solution. Faster than carbide scribing and easier to maintain than a laser, the PeddiBot-1100 utilizes modern layout marking plasma technology. Completely visible through rust and scale, plasma layout marking technology reduces error from manual layout and marking weld data onto a profile.

Modular Control

Control of the PeddiBot-1100 is carried out by a modern computer console. This control system consists of a standard desktop computer, monitor, keyboard and mouse. Part file information, sequence steps, machine controls, adjustment screens and alarms are all displayed on the intuitive and easy-to-use interface.

The Most Powerful Solution on the Market

Introducing the newest member to the Peddinghaus robotic family: the PeddiBot-1100 robotic thermal processor. Designed to revolutionize your beam cutting production, this advanced technology comes with the latest-generation Fanuc high-performance industrial robot. Specialized torch movements throughout plasma cutting and layout marking eliminate the need for grinding, resulting in more savings and profit in your pocket.

FineLine Plasma Torch

The PeddiBot-1100 comes equipped with a FineLine 300HD (300 amp) plasma cutting system. The FineLine 300HD is designed to deliver fast cutting speeds, exceptional cut quality, precise repeatability and high reliability to maximize productivity. The quick-disconnect torch enables fast and simple changeover, minimizing machine downtime.

Fanuc Robot for Reliability

The PeddiBot-1100 comes with the latest-generation, six-axis, high-performance industrial robot. A built-in robot collision guard is designed to eliminate damage to the torch due to accidental collisions. Fanuc robots are engineered for extremely high speed applications, and are known for their reliability to deliver repeatable precision with unparalleled performance.

Near Flange Cutting

One of the biggest challenges during beam cutting is the transition area from web to flange. The PeddiBot-1100 executes fast cutting sequences based on plasma techniques to cut away scrap material. This produces clean and sharp edge finishes, which helps to reduce the need for secondary processing such as grinding for weld preparation.

Measuring Cart System

A high speed measuring cart located above the infeed conveyor is designed to maintain accurate positioning of the material. A Fanuc servo motor with a precision encoder drives the measuring cart on a rail with wheels. This measuring system follows the material by exerting pressure to contact the workpiece. The measuring cart uses force feedback to detect the end of beams and comes standard with a lift system for fast reloading.

Integrated Layout Marking

Multi-axis plasma layout marking is a long-lasting and economical solution. Faster than carbide scribing and easier to maintain than a laser, the PeddiBot-1100 utilizes modern layout marking plasma technology. Completely visible through rust and scale, plasma layout marking technology reduces error from manual layout and marking weld data onto a profile.

Modular Control

Control of the PeddiBot-1100 is carried out by a modern computer console. This control system consists of a standard desktop computer, monitor, keyboard and mouse. Part file information, sequence steps, machine controls, adjustment screens and alarms are all displayed on the intuitive and easy-to-use interface.