Enter Today for a Chance to Win FREE Machinery

Gift cards and other Peddinghaus merchandise included

46331 mobile

TO

46331

WINNER

Normal text message rates apply. Text “STOP” to opt out. Text “HELP” for help. Up to 3 msgs / month. Terms https://www.peddinghaus.com/terms/1

We Are Stronger Than Steel

We do more than make machines for steel fabricators. We keep you ahead of the fabrication curve through unparalleled partnerships, constant research and development, industry-leading service, cutting-edge technology and quality components to create machines that are built to last. At Peddinghaus, our customers succeed.

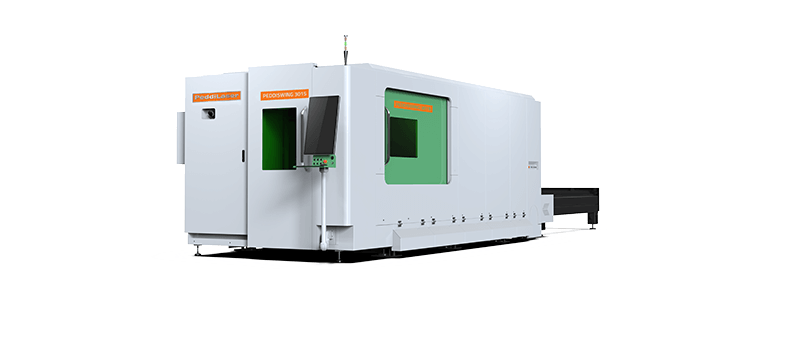

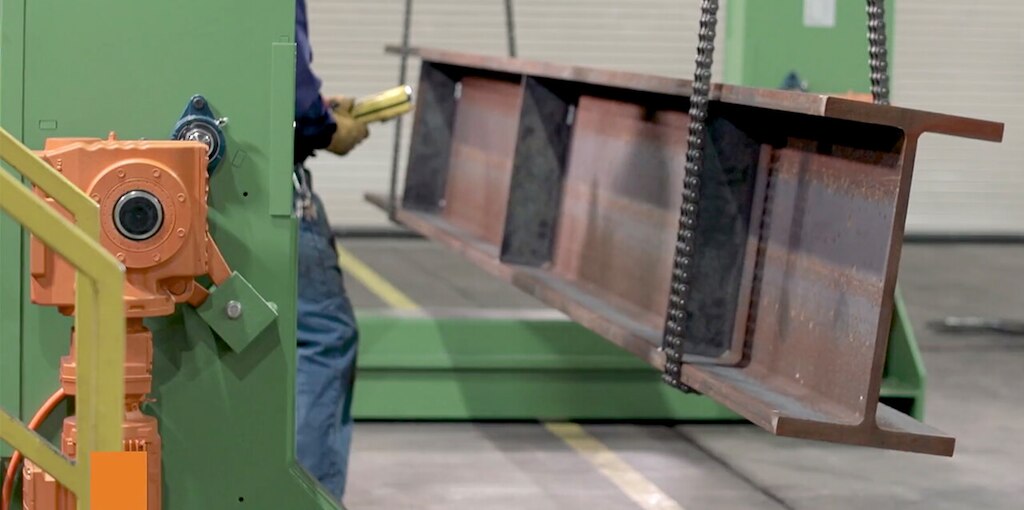

New Video Release

Reframing the Role of the PeddiBlast at Kard Welding

For a fabricator balancing high-volume bridge work alongside structural steel for buildings, the ability to control flow, timing and surface quality isn't optional, it's what determines whether projects move smoothly or pile up. When the second generation of the Osterloh family took ownership of Kard Welding in 2024, they w...

Latest News

YOU'RE INVITED to the Peddinghaus Customer Appreciation Event

Sign Me Up! -> www.peddinghaus.com/rsvpIt all comes down to this - the PeddiFinale! Join Peddinghaus for our grand finale Customer Appreciation Event and experience an epic celebration you won’t want to miss. This is THE party the steel industry will be talking about for years to...

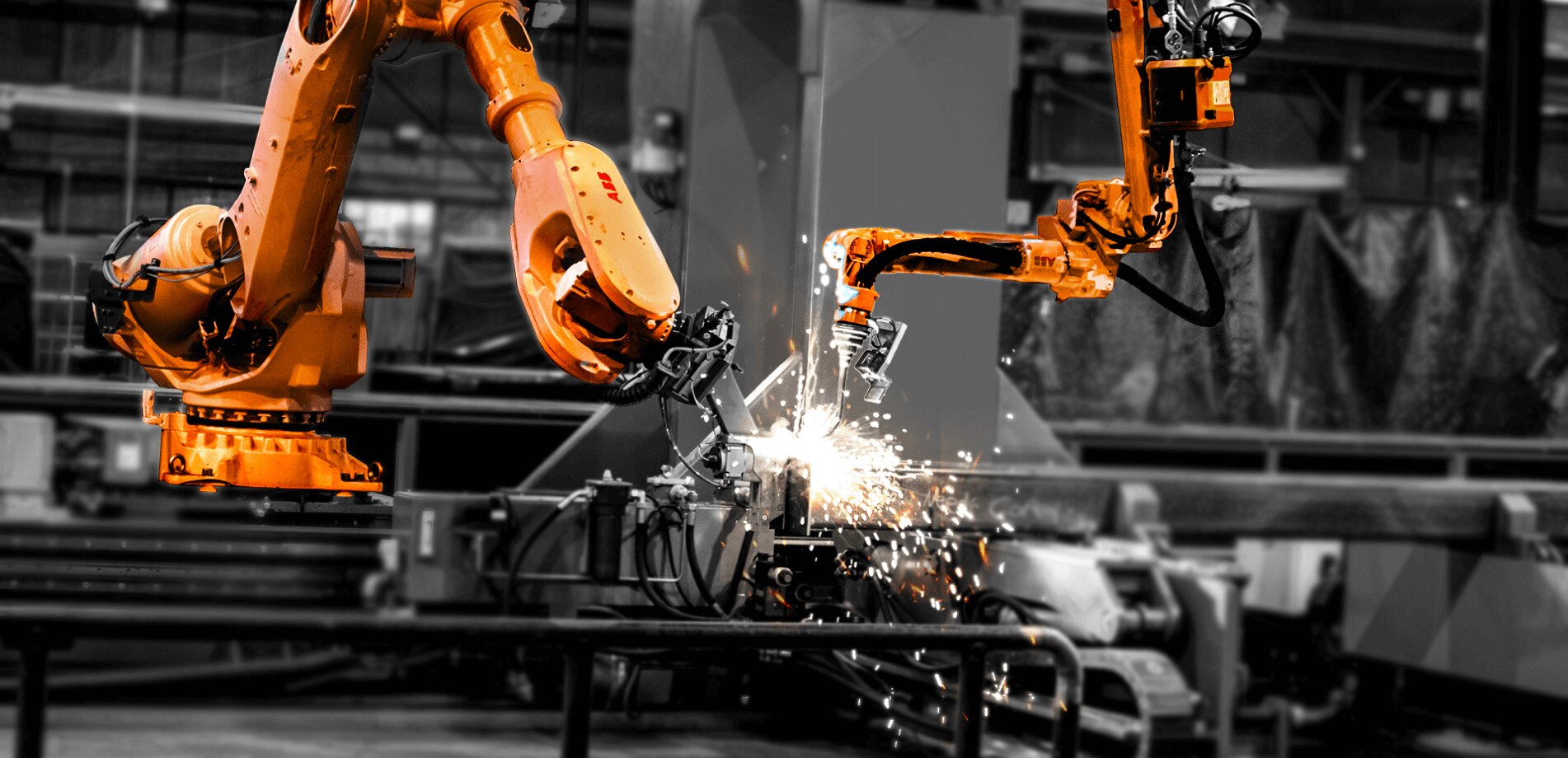

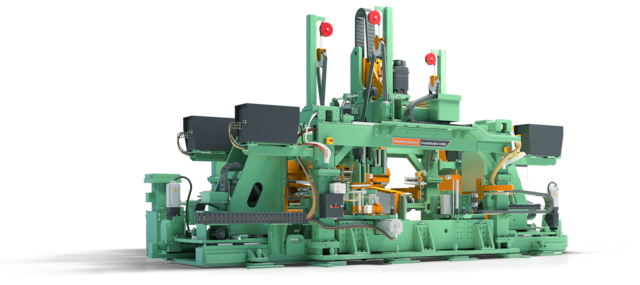

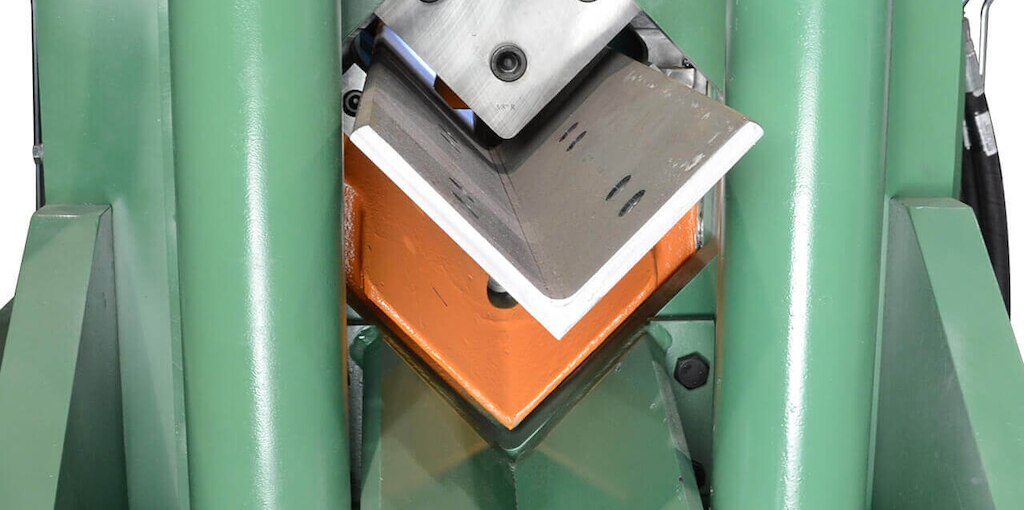

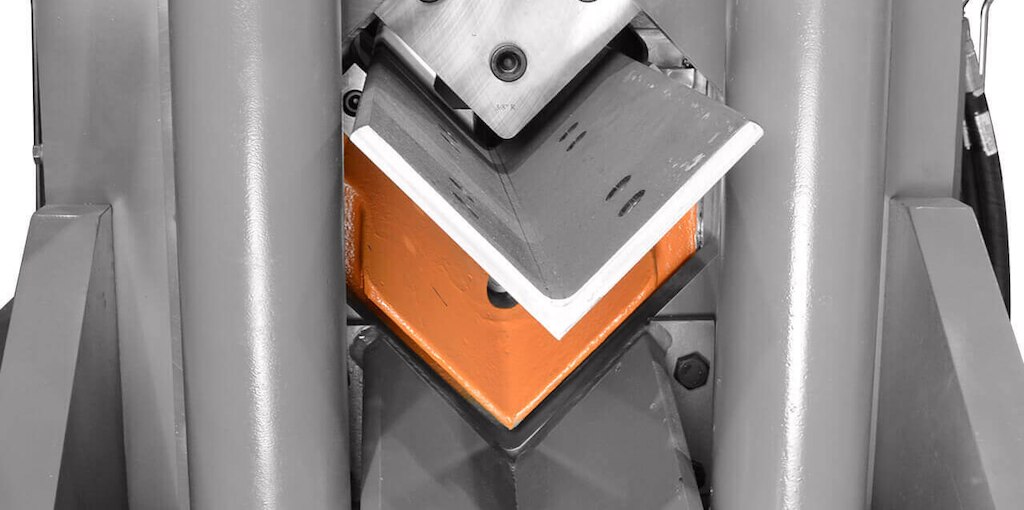

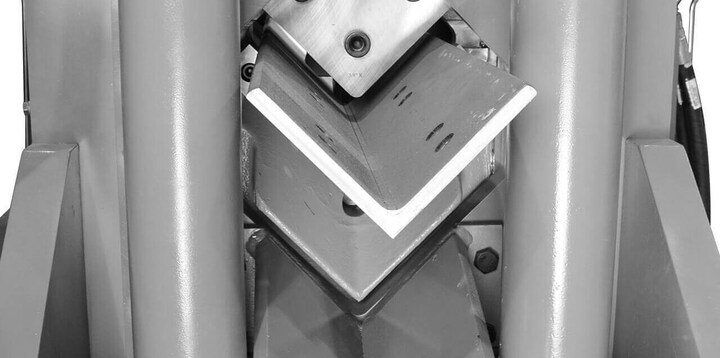

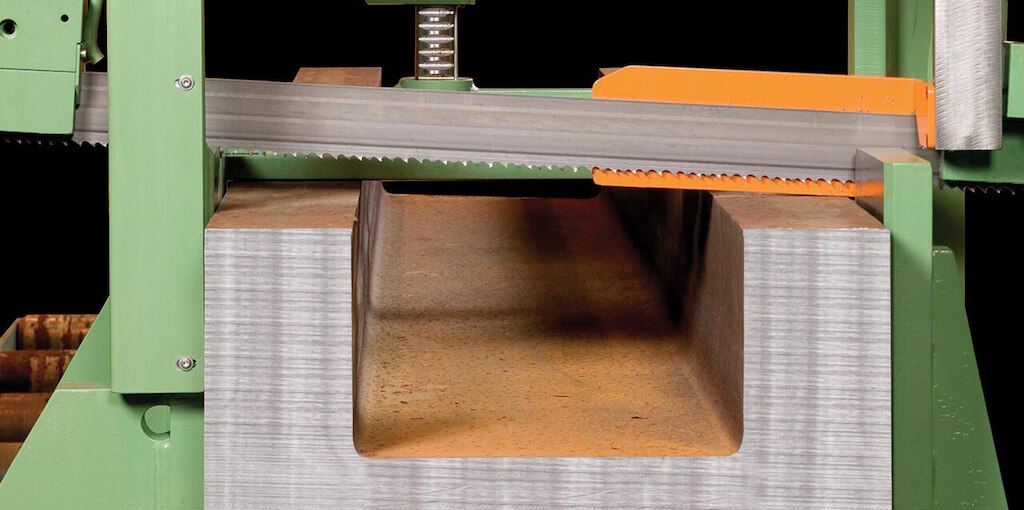

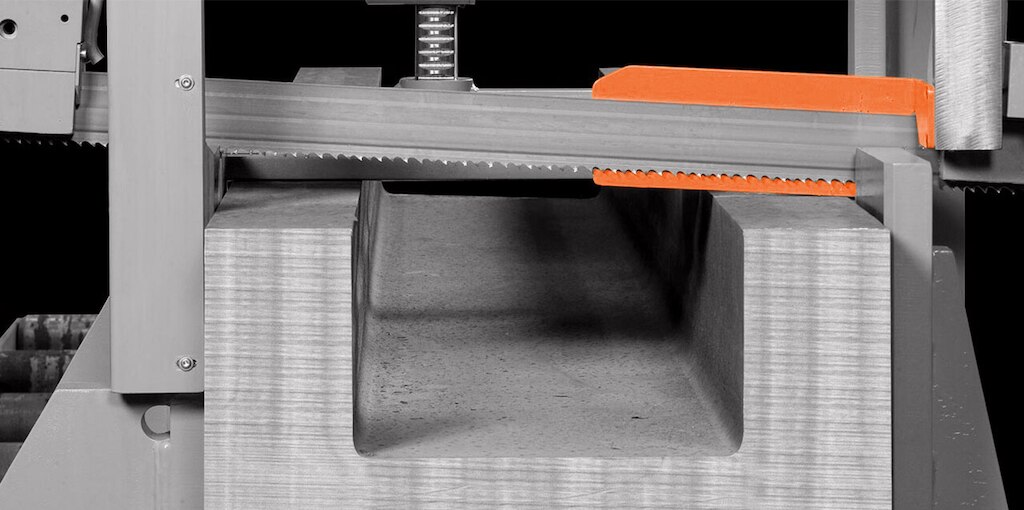

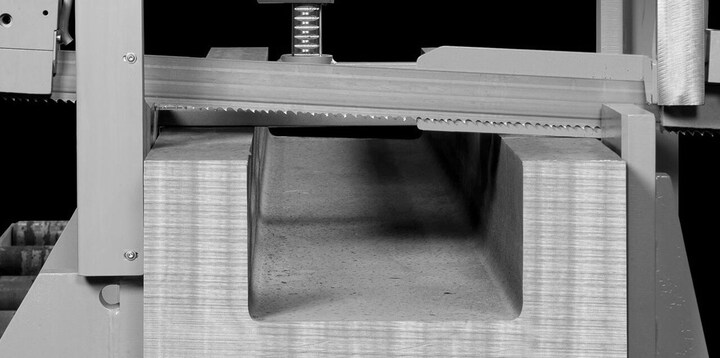

Superior in Every Category Against the Competition

Steel Fabricates Best on Peddinghaus Machines

1.5x Speed

Faster processing power leads to increased shop throughput

2x Strength

Built stronger to withstand the toughest material and the most taxing environments

3x Accuracy

Precision enhancements eliminate erection-site rework

4x Service

Reduced machine downtime with 24/7 support team

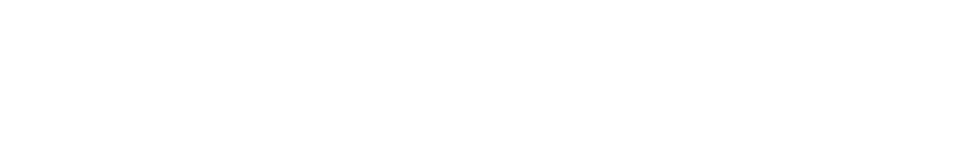

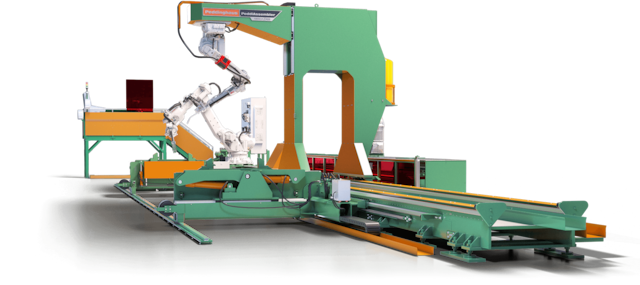

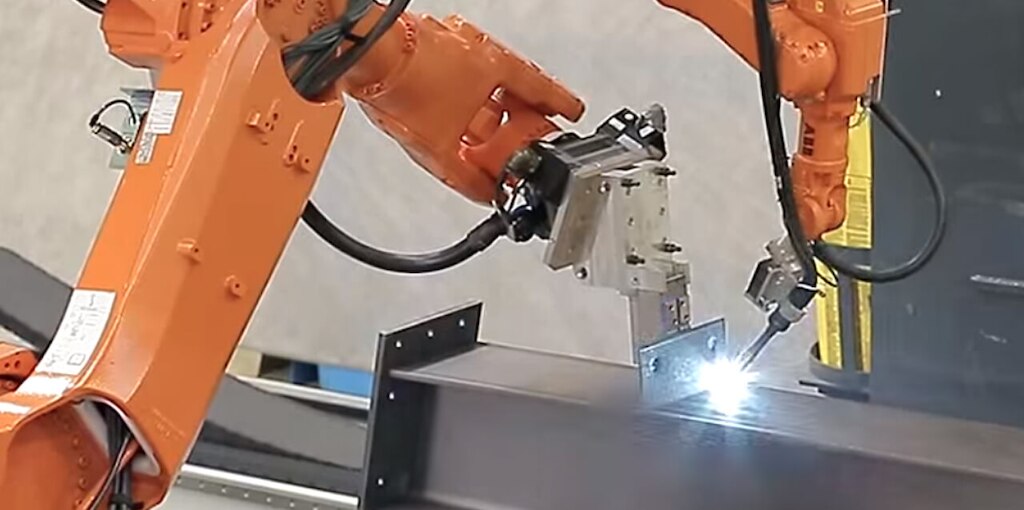

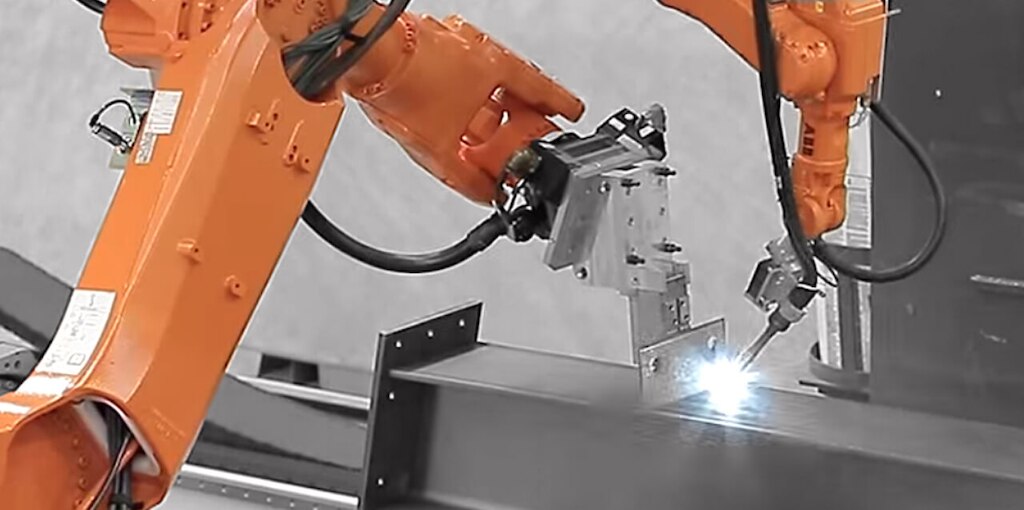

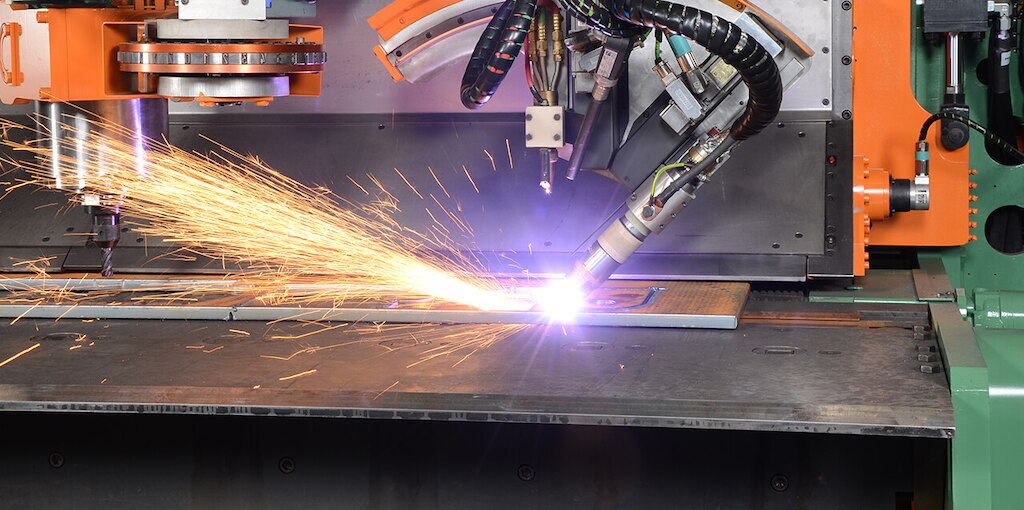

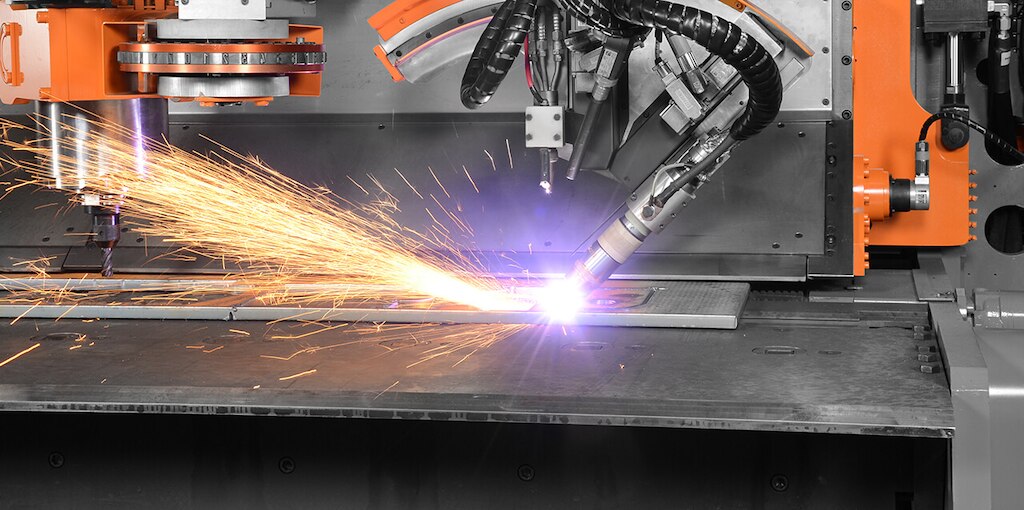

Robotic Automation Is Shaping the Future of the Structural Steel Fabrication Industry

Robotic features allow fabricators with complex applications to take advantage of cost savings offered by a compact, versatile and more productive option for processing. By providing constant material output to fitters and welders, robotics handle the heavy lifting and allow them to focus on assembling the end-product.

Machines Worldwide

Largest supplier of steel fabrication machinery in the world

-

9,000+

Machines

-

89+

Countries

-

7

Branches

We Empower the World’s Most Successful Fabricators

Don't just take our word for it, hear their stories