Overview

- Shot Blasting

- High Performance Turbines

- Abrasive Containment

- Wind Separator

- Bucket Elevator

- Shell Valve

- Maintenance Access Panels

- Manganese Steel Chamber

Blasting

Power

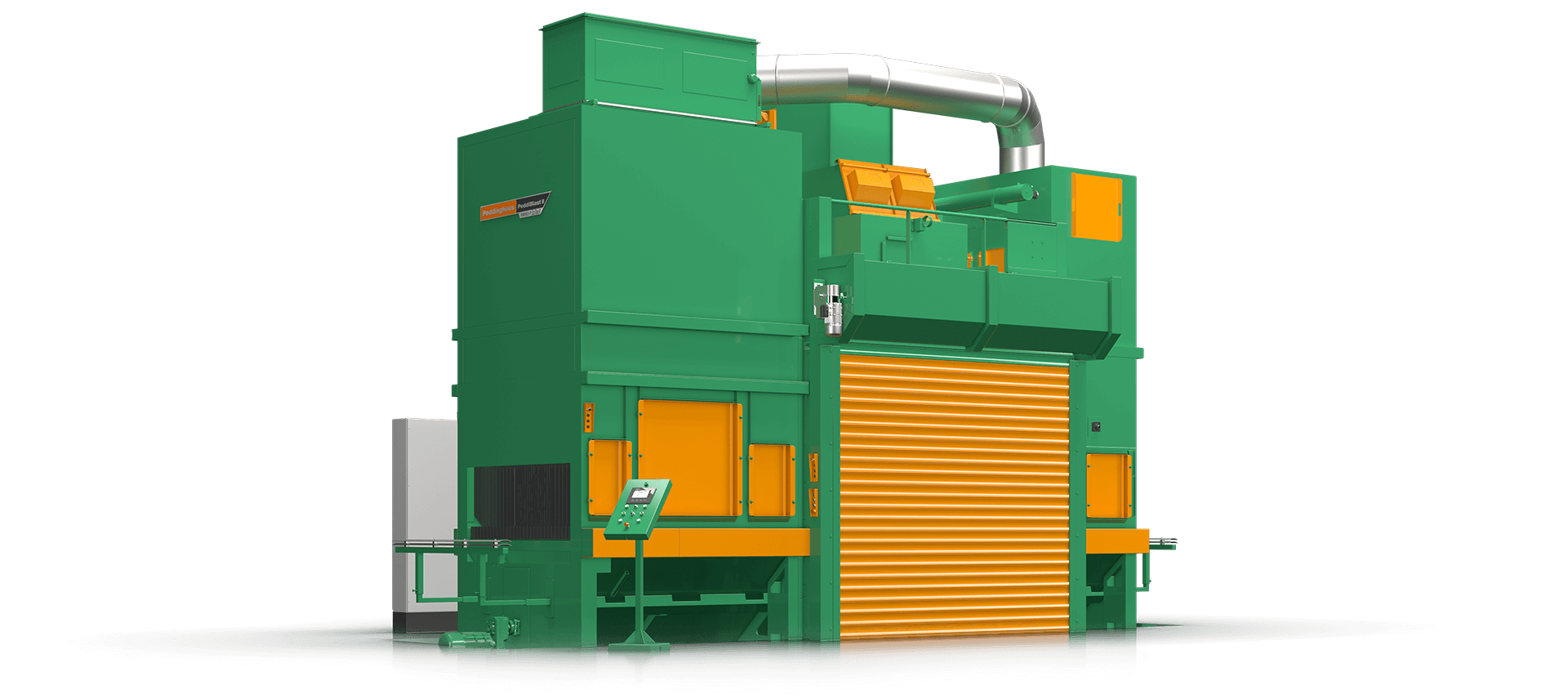

Powerful, Rugged, Efficient

Providing the best results with the least amount of abrasive is essential to any shot basting machine. Utilizing the PeddiBlast for all blast cleaning needs, fabricators receive parts rid of surface impurities in seconds.

End-Product Quality Control

Whether the fab shop is small or large, the PeddiBlast is completely configurable to each fabricators’ needs. High-powered turbines, simple maintenance, a cleaner shop and simple integration into existing layouts, this blasting system is the need for any fabricator looking for cleaner welds and improved high-grade paint adhesion.

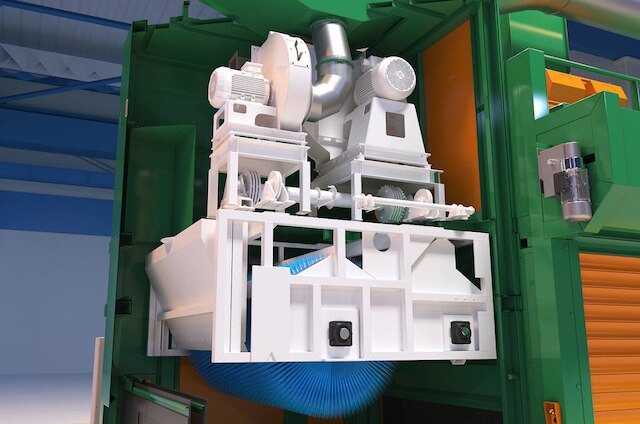

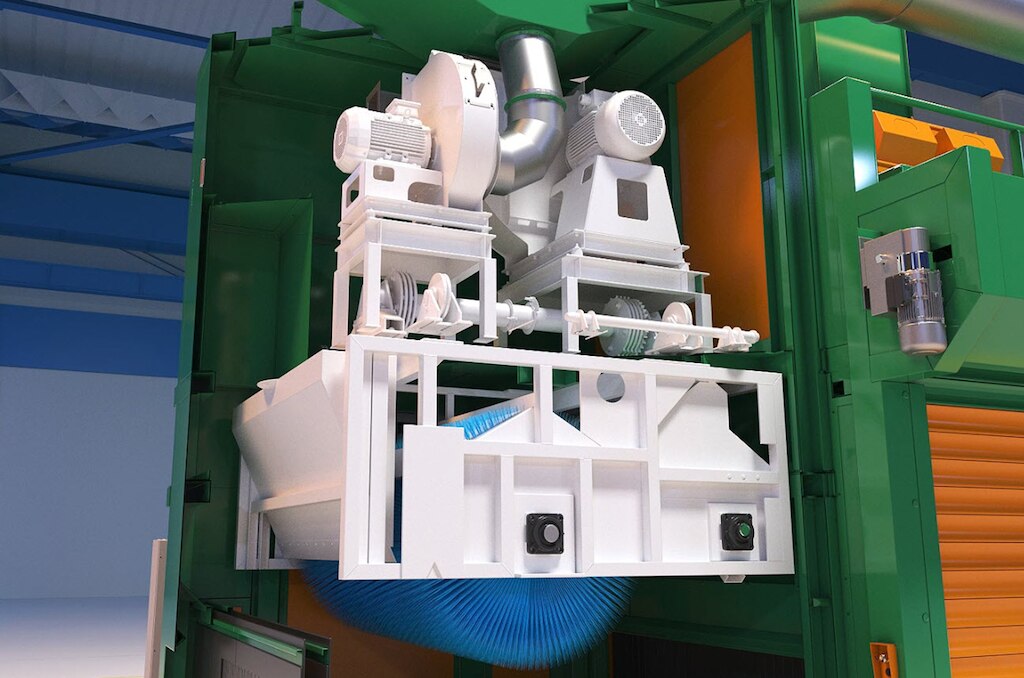

Powerful Blasting Turbines

Turbines on the PeddiBlast shot blast machine fall nothing short of strong, cost-effective power units. With easily replaceable throwing blades built from tough manganese steel, the turbine housing is wear-resistant. This ensures the turbine will be able to operate for prolonged periods of time between services.

Protective Blast Chamber

Designed to give the turbines unobstructed paths to material being processed within, the chamber ensures successful blasting procedures every time. The robust bolted and welded construction is guaranteed for long life in the zone of direct impact.

Abrasive Containment Curtains Keep Operators Safe

Each compartment within the PeddiBlast is outfitted with abrasive containment curtains designed to seal the machine during blasting operations, keeping abrasive off the shop floor and keeping operators safe from slips and falls.

New and Improved Workpiece Transport

The strategic spacing of the conveyor system rollers ensures the blast stream can pass between them without being exposed to the turbines' line of fire. Rollers are powered by an inverter-controlled infinitely variable speed geared drive, providing precise control over the material passage speed to achieve optimal cleaning results.

Combined Brush and Blower System

After processing, material is thoroughly cleaned to remove all remaining byproduct. A large rotating brush and a high-pressure downstream blower facilitate the removal of residual abrasive.

Ultimate Abrasive Control

An automatic abrasive refilling silo swiftly replenishes the abrasive circuit as needed, maintaining optimal levels for stable operation. Through an intricate separation and reclamation process, utilized abrasive is recycled, purified and readied for reuse, while specialized shell valves precisely regulate abrasive flow to the turbines.

Acoustic Sound Abatement Enclosure

Large soundproofed roller doors drown out the excessive noise commonly associated with shot blasting machines.

Powerful, Rugged, Efficient

Providing the best results with the least amount of abrasive is essential to any shot basting machine. Utilizing the PeddiBlast for all blast cleaning needs, fabricators receive parts rid of surface impurities in seconds.

End-Product Quality Control

Whether the fab shop is small or large, the PeddiBlast is completely configurable to each fabricators’ needs. High-powered turbines, simple maintenance, a cleaner shop and simple integration into existing layouts, this blasting system is the need for any fabricator looking for cleaner welds and improved high-grade paint adhesion.

Powerful Blasting Turbines

Turbines on the PeddiBlast shot blast machine fall nothing short of strong, cost-effective power units. With easily replaceable throwing blades built from tough manganese steel, the turbine housing is wear-resistant. This ensures the turbine will be able to operate for prolonged periods of time between services.

Protective Blast Chamber

Designed to give the turbines unobstructed paths to material being processed within, the chamber ensures successful blasting procedures every time. The robust bolted and welded construction is guaranteed for long life in the zone of direct impact.

Abrasive Containment Curtains Keep Operators Safe

Each compartment within the PeddiBlast is outfitted with abrasive containment curtains designed to seal the machine during blasting operations, keeping abrasive off the shop floor and keeping operators safe from slips and falls.

New and Improved Workpiece Transport

The strategic spacing of the conveyor system rollers ensures the blast stream can pass between them without being exposed to the turbines' line of fire. Rollers are powered by an inverter-controlled infinitely variable speed geared drive, providing precise control over the material passage speed to achieve optimal cleaning results.

Combined Brush and Blower System

After processing, material is thoroughly cleaned to remove all remaining byproduct. A large rotating brush and a high-pressure downstream blower facilitate the removal of residual abrasive.

Ultimate Abrasive Control

An automatic abrasive refilling silo swiftly replenishes the abrasive circuit as needed, maintaining optimal levels for stable operation. Through an intricate separation and reclamation process, utilized abrasive is recycled, purified and readied for reuse, while specialized shell valves precisely regulate abrasive flow to the turbines.

Acoustic Sound Abatement Enclosure

Large soundproofed roller doors drown out the excessive noise commonly associated with shot blasting machines.