Enter Today for a Chance to Win FREE Machinery

Gift cards and other Peddinghaus merchandise included

46331 mobile

TO

46331

WINNER

Normal text message rates apply. Text “STOP” to opt out. Text “HELP” for help. Up to 3 msgs / month. Terms https://www.peddinghaus.com/terms/1

We Are Stronger Than Steel

We do more than make machines for steel fabricators. We keep you ahead of the fabrication curve through unparalleled partnerships, constant research and development, industry-leading service, cutting-edge technology and quality components to create machines that are built to last. At Peddinghaus, our customers succeed.

New Video Release

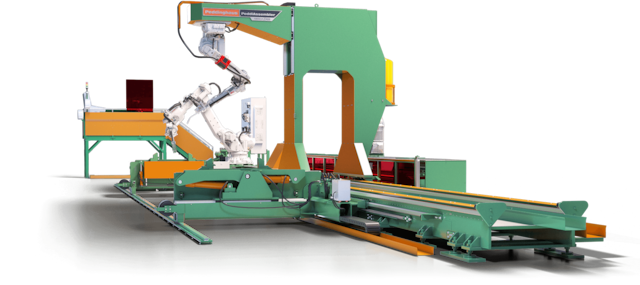

CNC Robotic Welding for Structural Steel Fabrication - PeddiAssembler Justification

The PeddiAssembler, equipped with advanced CNC robotic welding for structural steel, represents a significant advancement in the efficiency and accuracy of steel fabrication. Developed by Peddinghaus and powered by Lincoln Electric, this machine drastically reduces the time and labor required to weld beams, columns, and tub...

Latest News

In Their Automation Era

Down in sunny Bartow, Florida, S&S Welding recently revolutionized their 110,000-square-foot steel fabrication shop. With over two decades of experience in structural steel, S&S knows the time to embrace automation is now or never. In the last 6 months, S&S commissioned a new PeddiAssembler robotic welding system, an SPS plate sor...

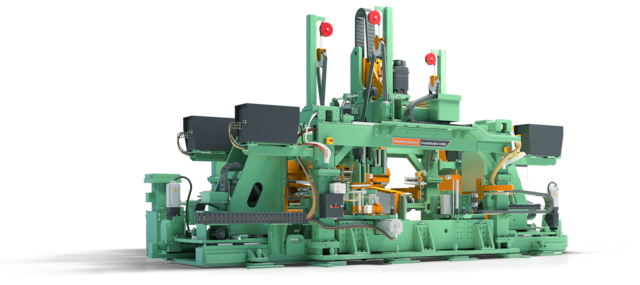

Superior in Every Category Against the Competition

Steel Fabricates Best on Peddinghaus Machines

1.5x Speed

Faster processing power leads to increased shop throughput

2x Strength

Built stronger to withstand the toughest material and the most taxing environments

3x Accuracy

Precision enhancements eliminate erection-site rework

4x Service

Reduced machine downtime with 24/7 support team

Robotic Automation Is Shaping the Future of the Structural Steel Fabrication Industry

Robotic features allow fabricators with complex applications to take advantage of cost savings offered by a compact, versatile and more productive option for processing. By providing constant material output to fitters and welders, robotics handle the heavy lifting and allow them to focus on assembling the end-product.

Machines Worldwide

Largest supplier of steel fabrication machinery in the world

-

9,000+

Machines

-

89+

Countries

-

7

Branches

We Empower the World’s Most Successful Fabricators

Don't just take our word for it, hear their stories